Layout & description of the Commercial RS Class Submarine

The RS Class Submarine is a reliable and economical, privately owned commercial subsea intervention vessel which may be chartered to qualified entities. It’s engineered for coastal water through continental shelf research, commercial and naval applications. It’s diesel / electric power configuration was chosen due to it’s maturity, reliability and historic safety. Our proprietary design allows for rapid independent transits and superior submerged autonomy with large area coverage capabilities.

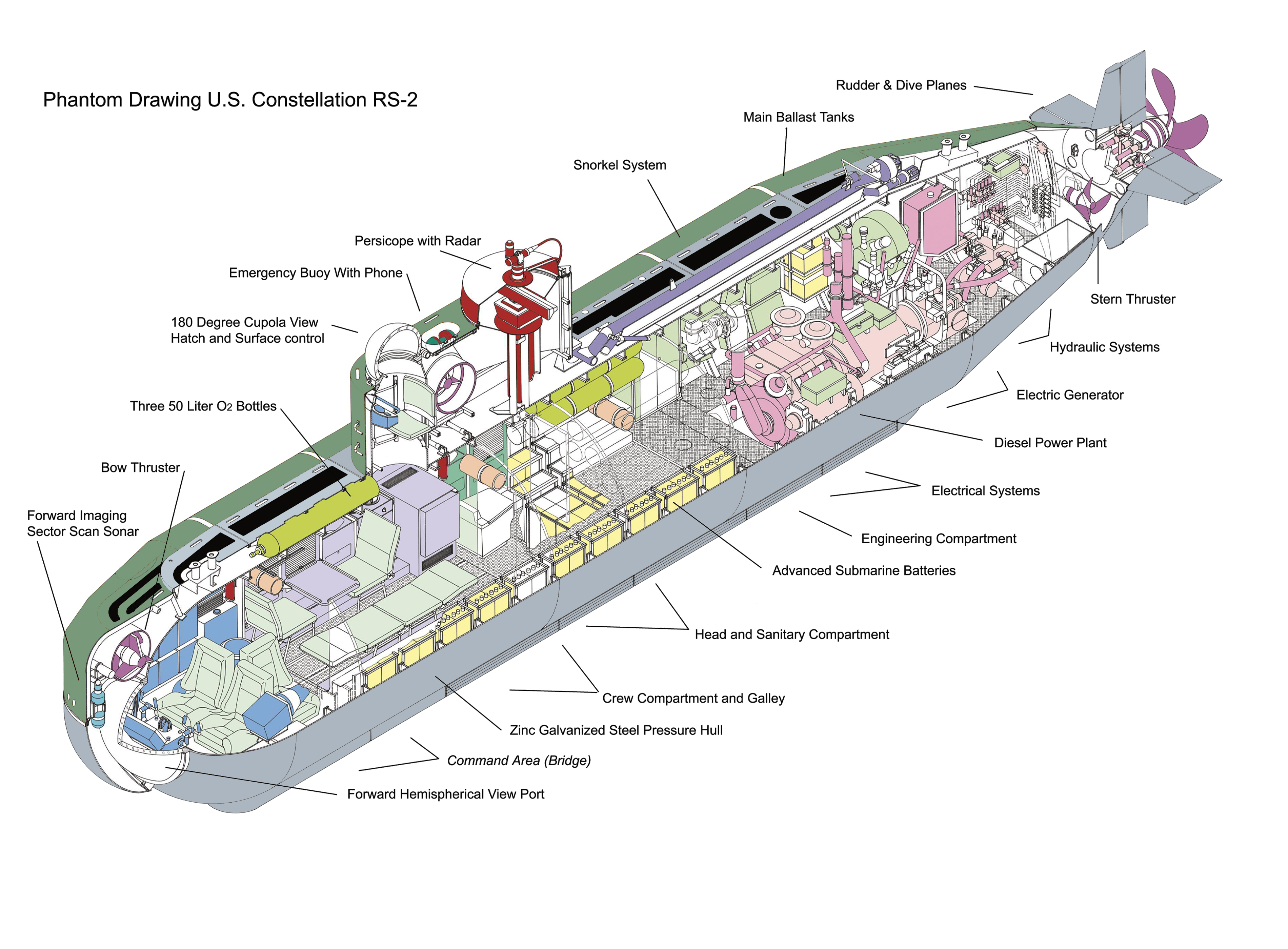

The fully zinc galvanized, high tensile strength steel pressure hull consists of three sections bolted together. The forward section is conical shaped with a hemispherical panoramic viewport installed in the bow. A cylindrical trunk located in the sail provides ingress and egress between topside and the forward compartment. The upper section of the trunk serves as an auxiliary surface conning station or as an additional viewport during submerged operations. Crew accommodations and a portion of the Next Generation Submarine Batteries are also located in this compartment.

Beyond the first bulkhead are the head and engineering spaces. This section houses the diesel engine, electric motor and generator, dc-dc converters, electrical distribution cabinets, various pumps as well as ballast and trim tanks. In the conventional propulsion mode, the submarine system consists of a diesel engine driving an electric motor / generator via a clutch and a hydraulic pumping aggregate. The main screw is positioned along the vessel’s centerline. Normal transits are controlled conventionally by rudders and dive planes. For maximum maneuverability at or near zero speed, the submarine is fitted with bow, stern and vertical lift thrusters. The latter, when not in use are retracted into the sail, forming a hydrodynamic shape. Folded out and downwards, the thrusters are unobstructed by the hull and allow for pinpoint maneuverability in 3 dimensions.

The Hard Ballast System consists of three internal tanks, and is used for adjusting the vessels buoyancy. The ballast system is gravity filled and emptied by drain pumps with back up systems. The main ballast tanks are formed into the exostructure and streamlined fairings. This system is used to achieve reserve buoyancy on the surface and is blown using HP air. The HP air tanks are regenerated by the vessel without the need of a support tender. Life support systems are comprised of three 50-liter O2 bottles with dosage valves and monitoring systems for O2, H2 and CO2. CO2 scrubbers utilizing SodaSorb® are installed in appropriate locations throughout the submarine.

The diesel engine has sufficient power to allow for rapid surface transits and charging of the HP air reserves and batteries simultaneously. The submarine can be operated during unpleasant weather in the snorkel mode, with only the air intake and periscope (Radar, Radio, GPS and Camera Systems) above the surface plane. The vessel has sufficient battery reserves to allow for long distance transits while totally submerged, minimizing weather related down time.

Features of particular interest:

Transport 4 (Scientists / Technicians / Engineers of your choice) and 2 Crew Members

Spacious and Comfortable Interior

1.1 Meter Diameter Forward Facing Hemispherical View Port

400+ Nautical Mile Surface Range at 8 Knots

Two, Six-Function Hydraulic Manipulator Arms

Accurate, Fully Integrated INS Navigation Suite*

Multi-Frequency Side Scan Sonar System (Sub-Bottom Profiler Option Available)

Forward Imaging Sector Scan Sonar System

High Resolution Digital Video Cameras and Recording System

Submarines can be custom fitted to your project’s specific needs.

Submarine Specifications:

Please call us at (732) 730-1500 for exact endurance and capability specifications.

* Uses customized software and inertial navigation system coupled to a DVL to meet exacting survey standards.